KAMA ProFold 74

Manual work was yesterday: today, the ProFold 74 folds and glues blanks into a multitude of print products automatically and cost-efficiently!

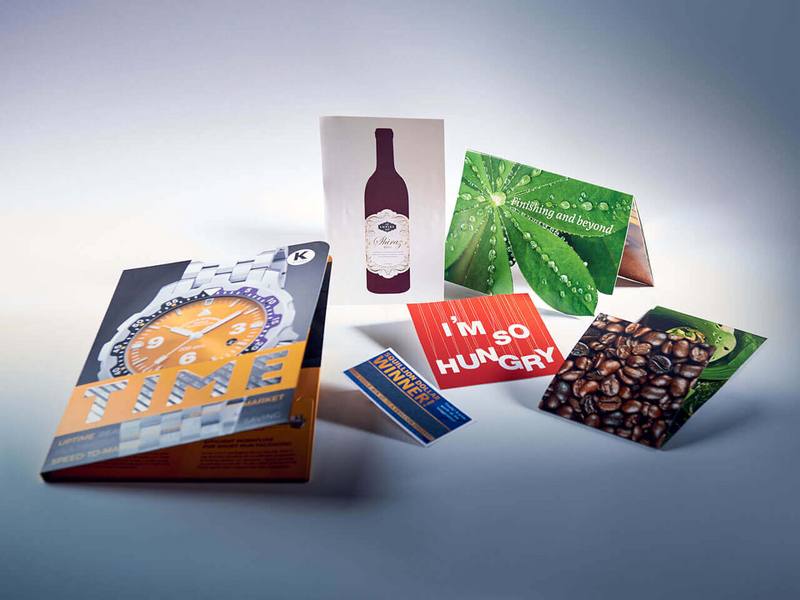

Whether presentation folders, folded cards, shipping envelopes, ticket pockets, cross folders and advent calendars or orders from the field of packaging, such as folding cartons with straight-line or crash-lock bottom.

Produce all these products in-house on the ProFold 74, benefit from shorter delivery times and extend your margins!

- Folding

- Gluing

- Dispensing

- Capacity Folding

Further orders that can be handled with the versatile ProFold 74:

- Inserting vouchers, cards, package inserts and product samples

- Dispensing labels, adhesive tape and pull strips

- Products with capacity folders

- Zig-zag folds for products with variable volumes

- and many other applications.

Short set-up times on the ProFold 74 – thanks to the JobPlanner software, innovative tools and the unique KAMA grid-type mounting system – mean that finishing of even short runs can be made profitable. Thanks to the flexible options for use, including for the packaging market, the investment costs for this multi-talent will be recouped very quickly.

Highlights of the ProFold 74

Wide range of applications

From commercial printing to packaging: the ProFold 74 is capable of manufacturing many different products.

5,000 folders with capacity folders, 18,000 ticket pockets or 24,000 folded cartons – folded and glued in an hour: the ProFold 74 can handle a wide range of commercial print jobs and packaging tasks.

Thanks to the short set-up times, the machine can be used profitably even on short runs.

Here are some product groups that run on the ProFold 74, each in many different blank variants:

- Dispensing

- Boxes

- Advent calendars

- Folding cards

- Dispensing adhesive tape

- Small products

- Cross folders

- Capacity folder

- Ticket pockets

- Inserting, envelopes

- Folding cartons

- Various

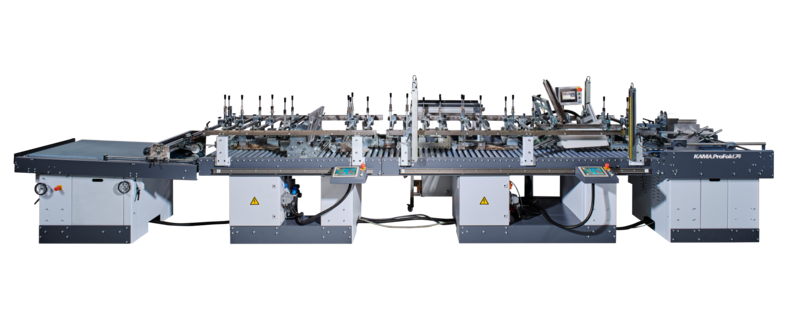

Modular machine concept

The machine grows with your tasks.

You purchase only what you need, and the machine grows in parallel to new services when you add them to your portfolio. All new developments for the ProFold 74 are retrofittable and are integrated in the JobPlanner software.

The configurator will help you to find out which modules and tools will be helpful for your portfolio:

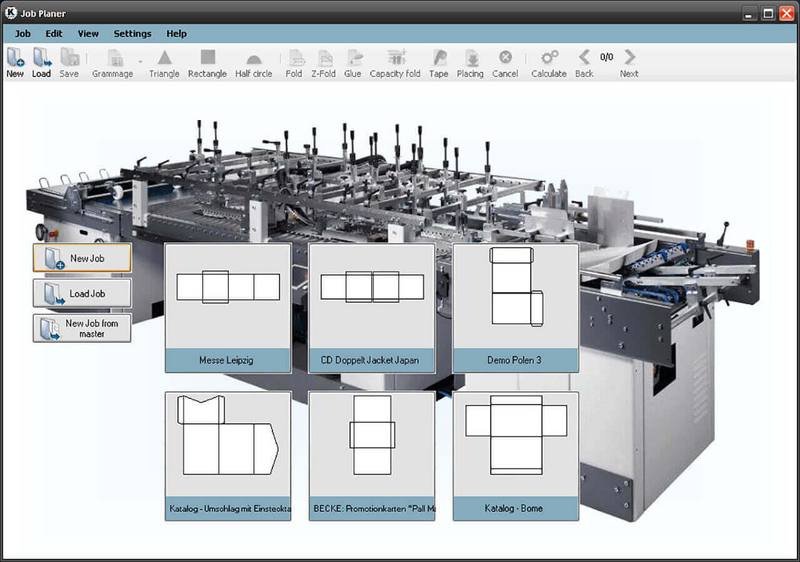

„JobPlanner“ Software

It’s all in the detailed calculations: from break-even to the set-up plan.

You enter the order data, and the JobPlanner software automatically calculates the costs, delivery time and break-even for the batch. The software also calculates the set-up plan with a corresponding item for every tool. Repeat orders are saved.

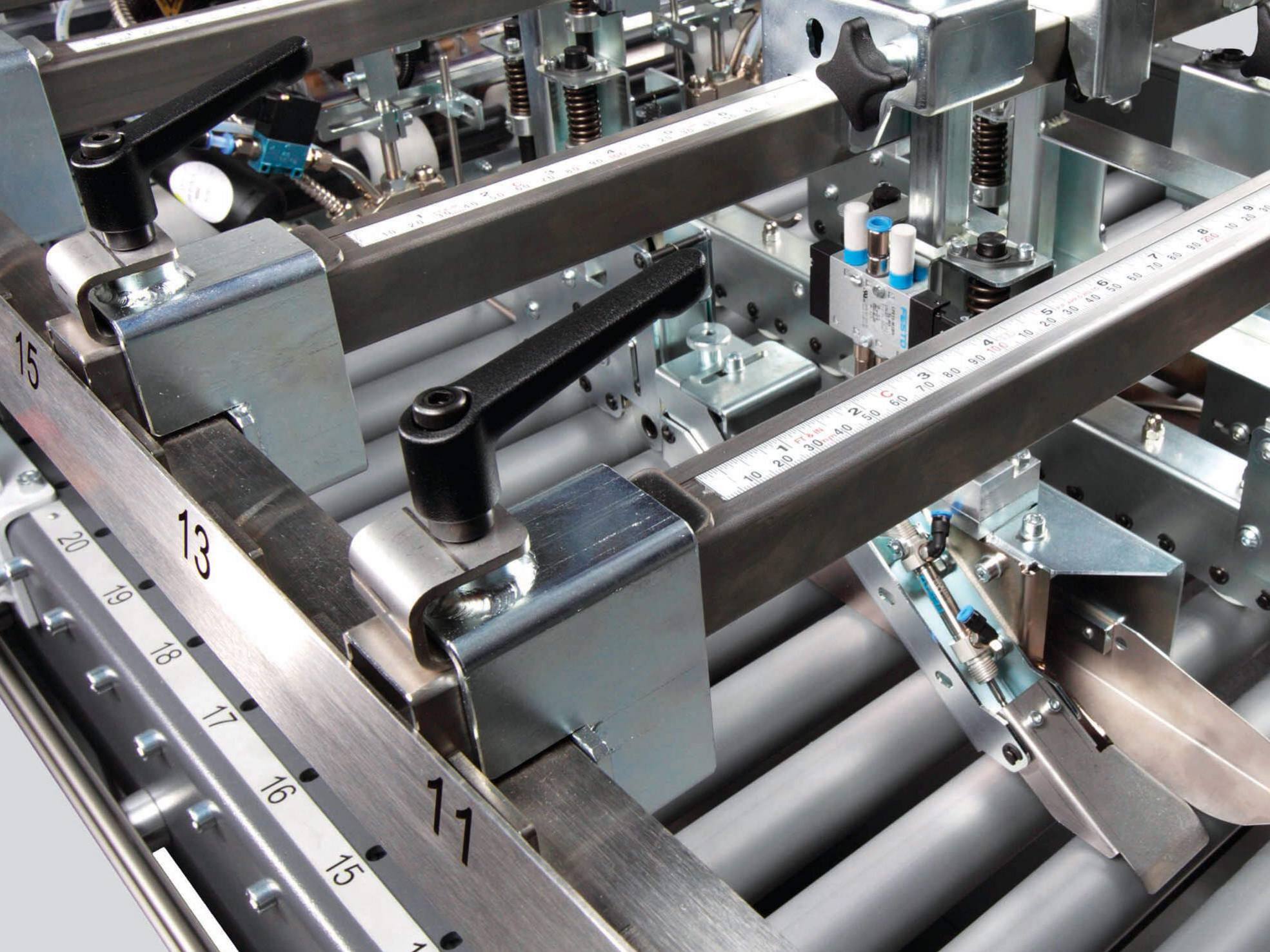

Fast set-up

… on the mounting system with clear lines.

The scaling along the machine and on the crossbeams shows the way: The layout is clear on the KAMA mounting system, and tools can be quickly located in the correct position with the aid of the quick-action clamps. Depending on the product being handled, use of the ProFold 74 can be profitable from print runs of 250 or 300. The set-up plan can be reproduced for repeat orders.

Dispensing

We go one better.

This tool allows you to dispense a wide range of different additions – e.g. vouchers, cards and calendars, package inserts or cosmetics samples etc.

Dispensing adhesive tape

Gluing – and let the customer seal it later.

This is a device that is often needed in practice. ProFold 74 folds and applies adhesive tape to envelopes, folded postcards and other products so that the customer can easily seal them later on.

Dispenser with pull strip

For tearing things open when you need to.

You want the customer to be able to open their product easily as well. This is why the ProFold 74 attaches the pull strip to the product at the same time.

Manufacturing capacity folders

Space for everything.

Orders with capacity folders are very complex to manufacture manually. When it comes to these products, the folder-gluer gluer can save a great deal of time indeed. The ProFold 74 is the only solution capable of manufacturing capacity folders from just 3 mm and up to 40 mm.

Creasing and perforating device

Everything is better with good creasing.

For products that are only cut prior to folding and gluing and do not run over a cutting station, the ProFold 74 will take care of creasing and perforating at the same time. Examples include greetings cards, folded cards, tickets, blanks or display panels.

Sliding control panel

Wherever you need it.

Practical and time-saving: The control panel slides along the machine, so it is ready to use wherever the operator is, enabling him/her to keep both hands free at all times.

Free rotation up to 360°

There's no such thing as impossible!

For once, this is not just a bold claim. From 1 to 360 degrees, the programmable device on the ProFold 74 will rotate the product exactly as far as required. So an exciting angle is perfectly possible.

Organisation system

In our tailor-made organisation system, all your tools are safely stowed away with minimal space requirements.

And of course they are always ready to hand.

Specifications – KAMA ProFold 74

| Material* | Heavy paper, Paperboard, Plastics |

| Grammage* | 100 – 600 g/m2 |

| Minimum blank size (W x L) | 100 x 80 mm |

| Minimum product size (W x L) | 50 x 80 mm |

| Maximum linear speed | 150 m/min |

| Max. performance* | 36.000 cycles/h |

| Max. performance for capacity products* | 6.000 cycles/h |

| Machine dimensions | 5.500 x 1.000 mm |

Options

Equipment options and systems for the ProFold 74 (Selection)

- Auto-lock bottom device for lock bottom boxes

- Barcode scanner

- Flat stack feeder or suction-belt feed board&

- Motorised alignment table (left/right)

- NEW: extended delivery belt

- Capacity folder device – 3 to 24 mm

- Pick & place for high-volume goods samples

- Cold glue system with pressing station

- Creasing and perforating device