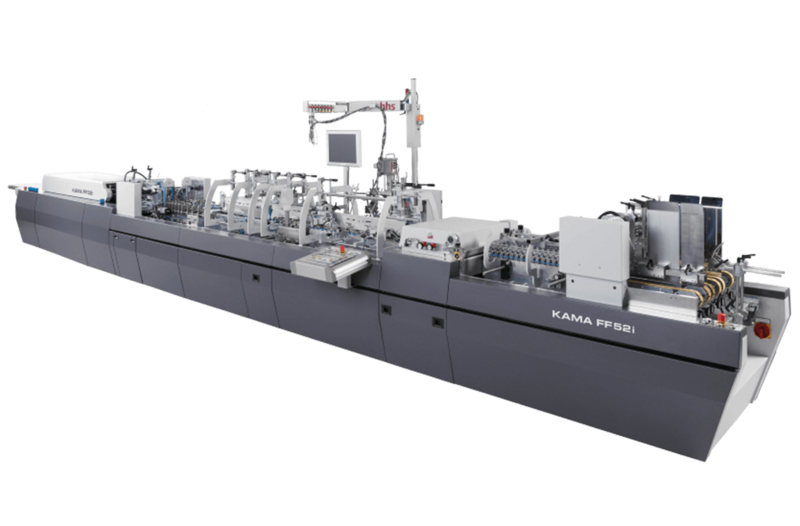

KAMA FlexFold 52i

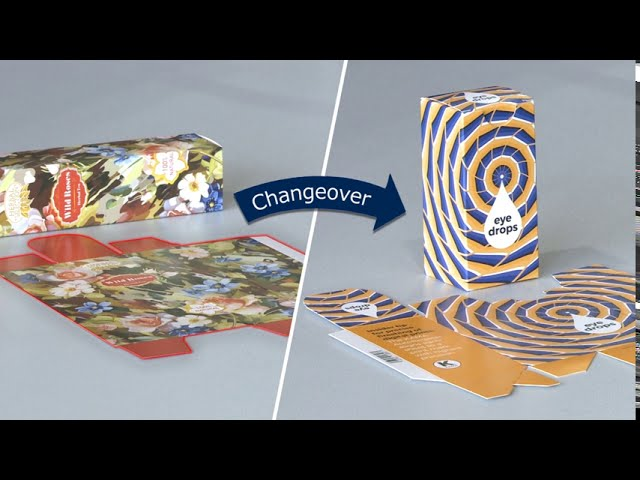

Cost-effective production of digitally printed folded cartons and small SKUs: this is the booming market for which we have developed the FlexFold 52i. The first folder-gluer for short runs is fully automatically adjustable and delivers order changeovers in a record time of just a few minutes. This means that the FlexFold 52i can handle far more than a hundred orders per day – whether straight-line boxes, cushioned packaging or lock bottom boxes.

- Folding

- Gluing

- Inspection

- Plasma Treatment

- Braille Embossing

Folder-gluer FlexFold 52i

The KAMA FlexFold 52i is tailor-made for print shops and packaging manufacturers who want to offer the following services to large brand manufacturers, but also to regional brands and local suppliers:

- Digitally printed folded cartons in changing designs with seasonal, regional or event-specific image designs (e.g. food or fashion)

- Personalised and individualised packaging (e.g. cosmetics and pharmaceuticals)

- Cartons in different languages (e.g. pharmaceuticals and healthcare)

- Partial orders – saving costs and keeping things up to date at all times

- Folded cartons with shorter time-to-market

The innovative FlexFold 52i machine received the EDP Award 2017 for the “Best folded carton solution” (European Digital Print Association).

Highlights of the FlexFold 52i

Job change in record time

Switching to the next order at the push of a button.

The FlexFold 52i folder-gluer automatically adjusts itself up for the box dimensions of the next order. The feeder, prefolder, gluing disc and the entire folding and gluing section are motorised and move automatically to the correct positions (KAMA patent). This makes job changes possible in less than 5 minutes.

Another USP: The FlexFold 52i is the only folder gluer capable of directly moving to the positions for the next job. Reference runs as on other machines are not necessary, which additionally accelerates job changes.

100 % inspection

Quality check according to the desired criteria.

100% inspections are a critical requirement for folded cartons e.g. for the pharmaceuticals sector. For the FlexFold 52i, KAMA offers different inspection levels with ejection of rejected parts:

- inspection of the glued seam,

- inspection of barcode and gluing tab code

- all the way up to complete inspection of the print image, colour, text and any contamination/soiling.

Defective blanks are automatically separated out.

For Print 4.0

Interface to the ERP system for fast data flows.

Short throughput times are a major plus for digital printing – and the workflow needs to follow suit. To ensure that data is exchanged efficiently even with large numbers of orders, the FlexFold 52i can be networked with your MIS via the Job Manager.

Fast familiarisation

Machine quickly under control.

Thanks to the high level of automation of the KAMA FlexFold 52i, new operators can quickly be trained. After a short, steep learning curve, even non-specialists have the fully automatic machine quickly under control.

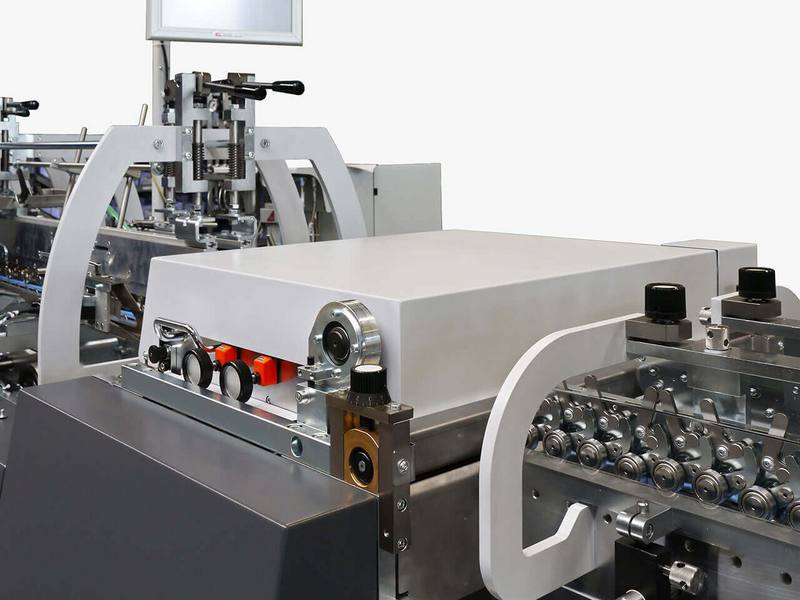

Sliding control panel

Wherever the operator needs it.

The control panel of the FlexFold 52i can be easily moved along the machine – to wherever the operator needs it, saving time and money.

Electronic order archive

Manufactured once, available to recall at any time.

Orders that are saved in the electronic job archive of the FlexFold 52i can be loaded directly as repeat orders.

KAMA AutoBraille

Inline Braille embossing with fully automatic positioning.

Positioning Braille embossing at record speed: On the KAMA AutoBraille for the FlexFold 52i, the pair of embossing wheels moves into position fully automatically. This is the only system on the market that can do this across the entire width of the machine, so that all possible embossing positions can be reached.

Tool change with automatic infeed is also ingeniously solved.

The FlexFold 52i Pharma folder gluer with AutoBraille is equipped with qualified systems for safety and validation at the highest level (EyeC ProofRunner Pharma, hhs Xtend³) and offers you the fastest job changes for pharmaceutical secondary packaging. The innovative solution for a higly attractive market!

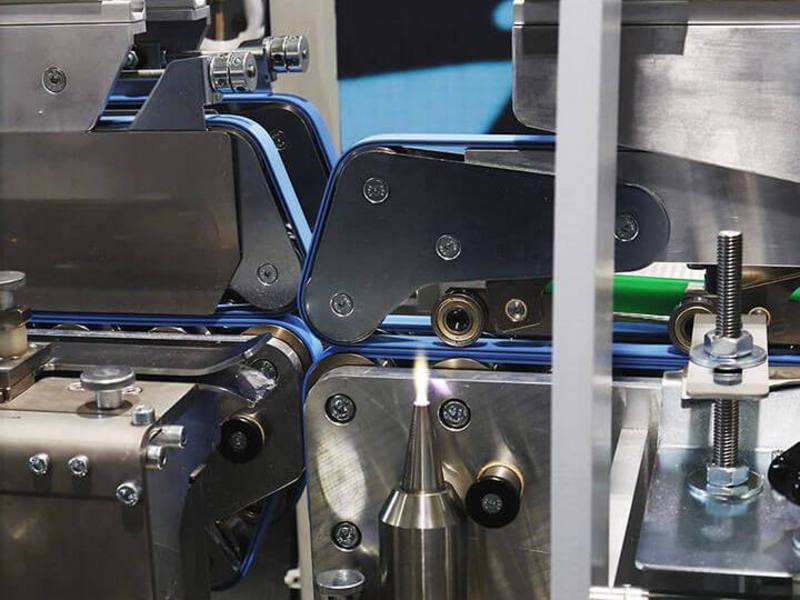

Plasma treatment

For smooth surfaces and UV coatings.

With plasma treatment, the FlexFold 52i can also permanently glue sealed and smooth surfaces – such as metallized cardboard and UV coated boxes. The process is ideal for lock bottom boxes with multiple adhesive surfaces, which are popular as packaging for cosmetics.

Solid and compact design

Small space requirements and a long service life.

The design and construction of the FlexFold 52i and all the materials used in it are selected for a long service life of the folder-gluer.

Packing system

Would you like to have a packing system for the FlexFold 52i? We offer various semi/automatic systems, which take the shingled stream of boxes directly from the FlexFold 52i delivery belt and erect them. For straight-line and lock-bottom boxes.

Specifications – FlexFold 52i

| Paperboard | 180 – 600 gsm |

|---|---|

| Micro-corrugated board | 0,4 – 0,9 mm |

| Performance* | 250 m/min |

| Straight-line boxes | Auto-lock bottom devices | |

|---|---|---|

| B | min. 10 mm | min. 35 mm |

| A + B | 40 - 250 mm | 70 - 250 mm |

| H | 50 - 300 mm | 50 - 300 mm |

Options

Equipment options and systems for the FlexFold 52i

- Inline inspection systems i1, i2, i3

- Upper gluing nozzles

- Plasma treatment

- Network integration via the KAMA Cockpit and the Job Manager software

- Unit for inline Braille embossing