KAMA ProCut 76 Foil

No other machine is this versatile. With 10 different applications available, the die cutting, embossing & embellishment machine ProCut 76 Foil will add flexibility to your finishing and enable you to meet customer demands and the latest trends in enhancement. A great opportunity for in-house value creation!

You want more?

Take advantage of the KAMA SBU automatic stripping and blanking system for the ProCut 76, which completely separates your blanks inline and doesn't require any job-related tools (KAMA patent). This saves you time and money - on every single job!

- Die Cutting

- Creasing

- Blind Embossing

- Braille Embossing

- Kiss Cut

- Hot Foil Stamping

- Hologram Application

- Hot Cut

- Stripping & Blanking

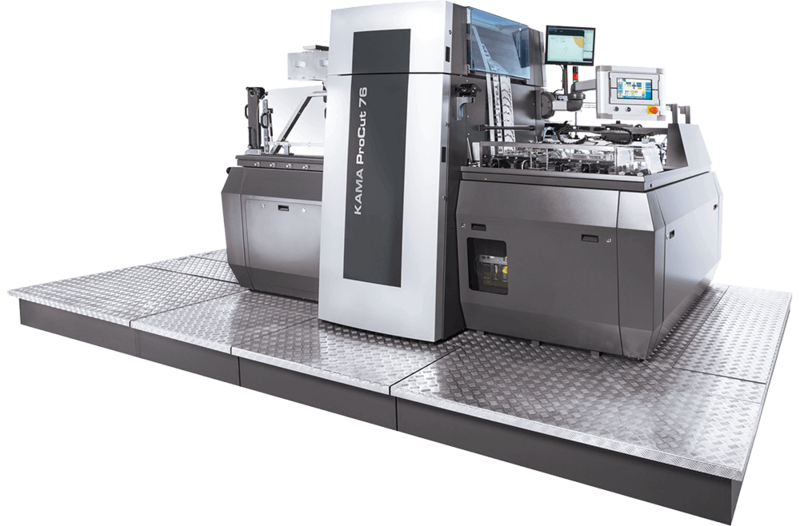

Die cutting, embossing and finishing machine ProCut 76 Foil

Produce outstanding print products for the commercial printing and packaging market – such as high-quality greeting cards and presentation folders, product labels for luxury brands, vouchers/gift certificates, embossed wine labels or self-adhesive labels, all the way up to version-controlled and personalised folded cartons. Whether conventionally or digitally printed: KAMA solutions reliably deliver precisely finished blanks and products.

ProCut 76 Foil is the ideal successor for worn-out cylinders and will help you take post-press to a new level: With three times the output, unrivalled registration accuracy and more options for creating value. The finishing die cutter is network capable and used all around the world by commercial printers, finishing companies and in packaging.

Highlights of the ProCut 76 Foil

All-in-one

Many applications, flexible in use, more added value.

Die cutting &embellishment with just a single investment: The ProCut 76 Foil covers both areas and is extremely flexible in use!

Cutting, creasing, perforating, Braille - and finishing with hot foil and holograms for increased security? It’s all in there. Plus further options like kiss-cutting of labels and hot cutting of plastics.

Ideal for print runs of 100 to 500,000 or more.

Quick set-up times

It’s easy and it's quick:

You can change over the KAMA ProCut 76 Foil from a cutter to a hot foil embossing machine in a matter of a few minutes. And vice versa. This flexibility is courtesy of the simple foil guidance system, the special KAMA heating system, the pneumatic tool locking mechanism and many other clever details that allow small or personalised runs to be processed and finished profitably. And ensuring that you can deliver quickly.

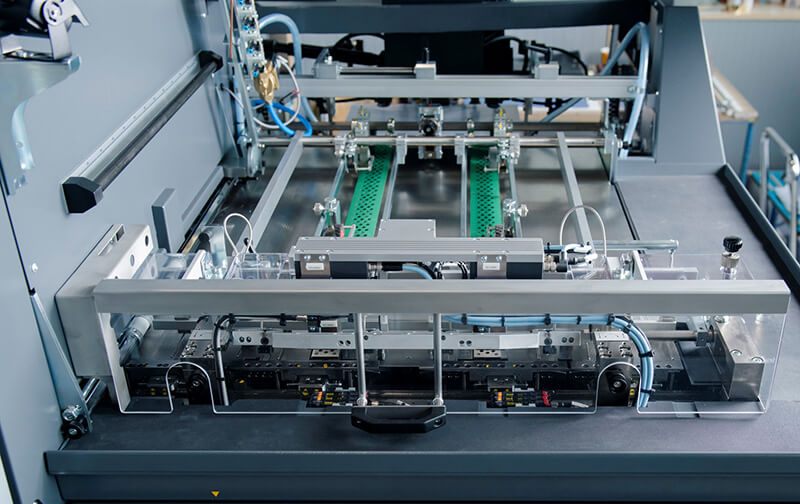

Highest registration accuracy

Even for most challenging orders.

Register? Perfect! The KAMA gripper achieves the highest registration accuracy in the market and doesn not need to be readjusted like other systems. For die cutting, embossing and embellishment with an accuracy of a tenth of a millimetre.

Maximising uptime

Time-saving features

Three factors ensure that the KAMA ProCut 76 Foil offers unrivalled uptime: the short set-up times, the quick-change heating plate system and the mobile KAMA heating plate. The machines are very quick to heat up, and no time is wasted during the cool-down. This really counts when it comes to short runs.

For orders with hot foil finishing, uptime can be boosted even further with the CPX, as it ensures that all positioning work takes place outside the embossing machine.

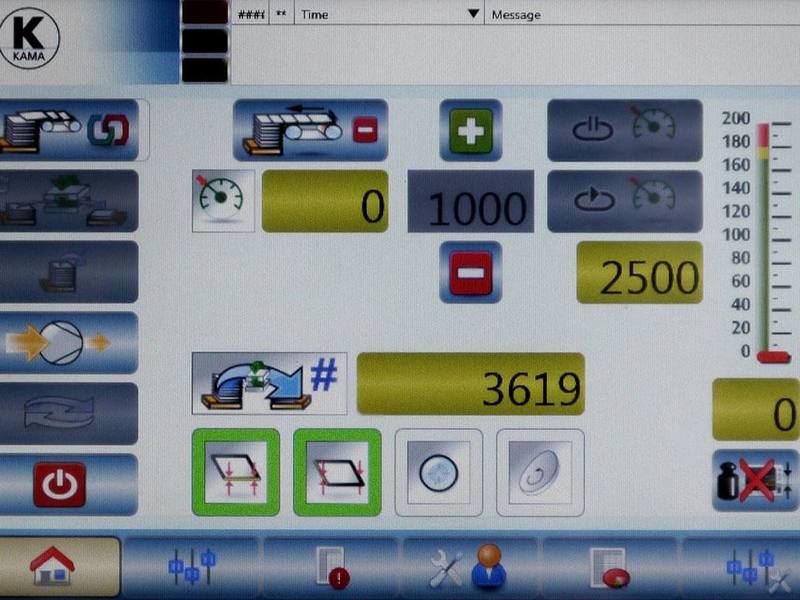

State-of-the-art servo technology

More output, more embossing time.

The main servo drive for the ProCut 76 Foil increases output during hot foil stamping by 50%. Alternatively, it is also possible to extend the embossing time for more complex embossing jobs.

The output remains the same, as the remainder of the stroke is accelerated to catch up the lost time. For the best embossing performance – both in terms of quantity and quality.

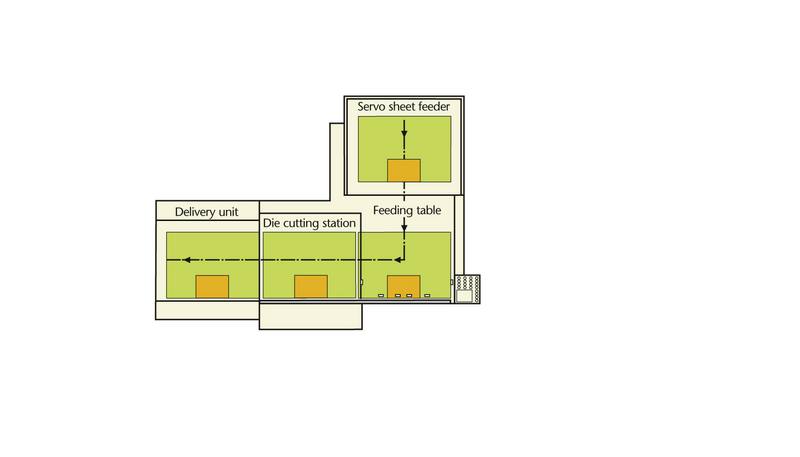

Small footprint

Lots of applications in a small space.

With a footprint of around 12 m2 including the platform, the ProCut 76 Foil makes do with very little space. Sheets are transported at a right angle in the system, so the finishing die cutter can be positioned in a corner area.

Continue using your existing tools

Thanks to the universal chase on the KAMA die cutter, you can continue to use your existing tools without any problems whatsoever. This also applies to small cutting dies.

AutoRegister AR3

NEW: AutoRegister AR3 additionally provides "skew adjust" - for maximum register accuracy with cut sheets adn twisted sheets, multiple embellishment and most demanding packaging.

Specifications of the ProCut 76 Foil

| Paper | from 100 g/m² |

| Paperboard, micro-corrugated board | max. 1,500 g/m² (bzw. 1.8 mm) |

| Plastics (PET, PP, PVC) | max. 1,500 g/m² |

| Maximum sheet size | 760 x 600 mm (29 15/16 x 23 5/8 in) |

| Minimum sheet size | 279 x 210 mm (11 x 8 1/4 in) |

| Speed* | 5,500 sheets/h |

| Cutting force | 165 t (1.65 MN) |

| Maximum cutting size | 743 x 585 mm (29 3/8 x 23 1/16 in) |

| Gripper margin | 10 mm |

| Dimensions (length x width) | 4.87 x 2.69 m |

Options

Example equipment for the ProCut 76 Foil

- The KAMA AutoRegister aligns every individual sheet based on the print image. Perfect for post-press and finishing in digital printing.

- Main servo drive with asynchronous stroke travel for higher output or extended embossing time during hot foil stamping.

- Universal chase for existing and smaller cutting dies

- 3-fold stamping systems for hot foil and holograms

- Quick-change heating plate system for hot foil/holograms

- Module for hot cutting and creasing of plastic materials for clean corners and smooth edges

![[Translate to English:] Efficient short run finishing on KAMA ProCut 76 with tool-free stripping & blanking](/cdn/_processed_/6/9/csm_efficient_short_run_finishing_on_kama_procut_76_with__tool-free_stripping___blanking_22102c428f.png)