KAMA ComCut 76

When is the right time to replace old cylinders?

The KAMA ComCut 76 makes the decision easy: The solution is the entry-level successor for platens and cylinders and offers all relevant cutting, creasing and embossing applications with double to triple the productivity. In short: You‘ll get professional functionality at an entry-level price.

- Die Cutting

- Creasing

- Blind Embossing

- Braille Embossing

- Kiss Cut

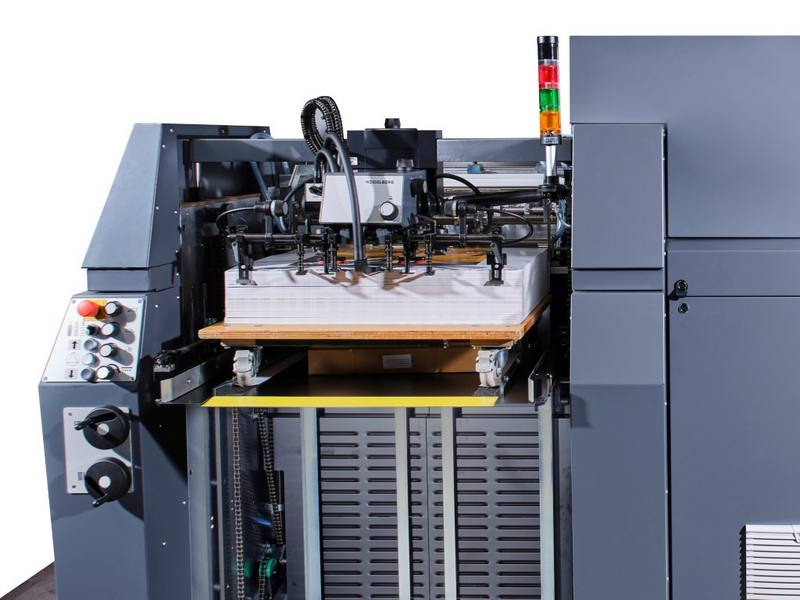

The modern ComCut 76 flatbed die cutter

The ComCut 76 is based on the proven platform of the KAMA ProCut, which has been successfully installed worldwide, and is manufactured in Germany using original components. The ComCut 76 offers the applications die cutting, creasing, perforating, embossing, Braille embossing and kiss-cutting in constant output quality and makes converting faster and more efficient with short makeready times.

All in all, a modern flatbed die cutter with contemporary safety that even young operators enjoy working on and that pays for itself with just a few hours of utilisation.

Highlights of the KAMA ComCut 76

Fast changeover with precision

Clear advantage of the flatbed die cutter.

Fast job changes are a must for short and medium runs. For the ComCut 76, jobs are prepared quickly, repeat jobs can be set up in just 5 minutes. And when it comes to accuracy, the flatbed die cutter has the edge anyway.

Seamless transition

Existing cutting dies? Simply continue to use them!

Existing die-cutting tools for platens and cylinders can be easily used further with the universal locking frame. Operators are quickly trained on the ComCut 76 and quickly become familiar with the machine. Operation is possible at the feeder (touch panel) as well as at the delivery side.

This ensures a seamless transition to the more profitable ComCut 76.

High profitability

You can count on this machine!

The ComCut 76 pays for itself with just a few operating hours per month - even compared to a depreciated cylinder. Short makeready times, multiple output and efficient loading: Piles of sheets on the pallet from the printing press can be placed directly in the feeder of the ComCut.

Add to this an attractive financing model.

Growth in the portfolio

More fields of application.

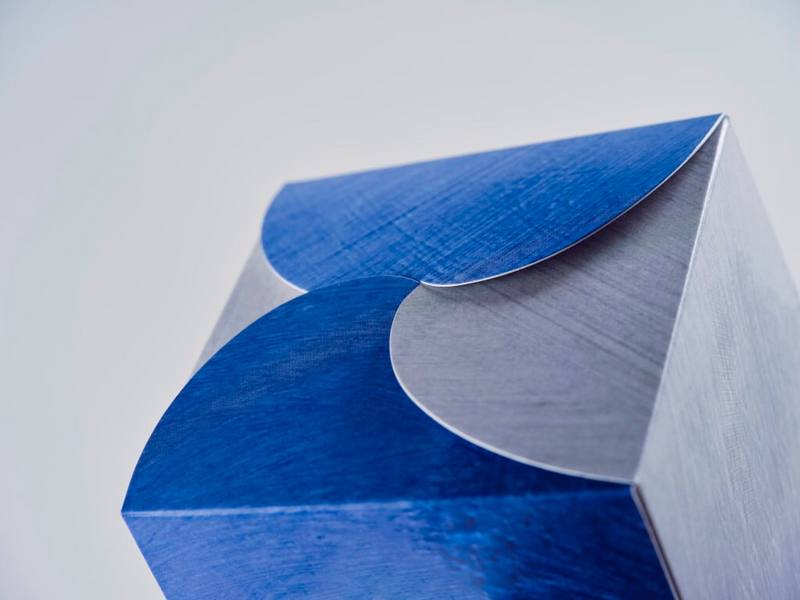

Thanks to safe and gentle sheet guidance in one plane on the KAMA die-cutting machine, hardly any (or no) holding points are needed. This delivers high-quality blanks and speeds up stripping - also relevant for folding box production. New fields are opening up.

Large-area blind embossing and high-low embossing are also possible with the ComCut 76.

Compact machine - Made in Germany

High-quality manufacturing ensures a long service life.

The ComCut 76 is manufactured in Dresden using original components. This means that, like all KAMA solutions, it stands for durability and a high resale value. The control cabinet is integrated into the ComCut 76 and the compact machine requires little space.

Specifications of the ComCut 76

| Paper | from 120 g/m² |

| Paperboard, micro-corrugated board | max. 1,500 g/m² (bzw. .,8 mm) |

| Plastics (PET, PP, PVC) | max. 1,500 g/m² |

| Maximum sheet size | 760 x 600 mm (29 15/16 x 23 5/8 in) |

| Minimum sheet size | 279 x 210 mm (11 x 8 1/4 in) |

| Speed* | 5,500 sheets/h |

| Cutting force | 165 t (1.65 MN) |

| Maximum cutting size | 743 x 585 mm (29 3/8 x 23 1/6 in) |

| Gripper margin | 10 mm (0.394 in) |

| Dimensions(length x width) | 4.90 x 2.70 m (193 x 106 in) |

Options

Example of equipment for the ComCut 76

- Universal locking frame for use of existing cutting tools (standard)

- Magnetic frame for die cutting plate with finest contours

- Blind embossing frame

- Antistatic device for laminated materials and plastic